UV printer have become increasingly popular over the years, as they allow businesses to print high-quality images on a wide range of surfaces. Choosing the right model is crucial for businesses that rely on high-quality printing. With the proliferation of Chinese UV printers in the market, selecting the right printer can be a daunting task. However, with some key considerations, you can find the best UV printer that meets your business needs. Let’s talk about some aspects to consider when selecting a UV flatbed printer from China, including the factory, after-sales services, and quality.

Factory is preferred option

Using a factory as a source of goods or products has many benefits and is often a preferred option for many businesses or consumers. The factory where the UV flatbed printer is manufactured is an essential aspect to consider when selecting a UV printer. Most of factories have the necessary certifications to manufacture printers. have a clean, organized, and efficient production line. if the factory has an R&D department that continuously updates and improves the printer’s technology will be better.

Another critical aspect to consider is the quality of the uv printer components. Ensure that the printer components are of high quality and sourced from reputable suppliers. Check if the factory has a quality control team to test and inspect the printer’s components before assembling them into the printer.

One of the major advantages of purchasing directly from a factory is that the prices are typically lower as there are no intermediaries involved in the supply chain who add markup to the product.

After-sales Services

After-sales service is a critical aspect of any purchase, and this is particularly true when it comes to printers. It is essential to look for a uv printer manufacturer who offers good after-sales service to ensure that you can easily maintain and repair your printer when needed.

One important factor to consider is whether the manufacturer has a technical support team that can assist you in case of technical problems. Ideally, you should look for a manufacturer that offers round-the-clock support so that you can quickly resolve any issues that arise.

Another consideration is the quality of the support provided. You should look for a manufacturer that offers knowledgeable and friendly support staff who can help you troubleshoot any problems that you may encounter. Ideally, the support team should be able to provide you with clear and concise instructions on how to resolve any issues, and they should be able to do so in a timely manner.

Finally, it is worth considering the time zone difference between your location and the manufacturer’s location. If you are located in a different time zone from the manufacturer, it may be difficult to get the support you need in a timely manner. In this case, it may be worth looking for a manufacturer that has support staff located in your time zone or that offers extended support hours to accommodate different time zones.

Independence Technology

When it comes to UV printers, independence technology is important because it ensures that the printer is built from the ground up with high-quality components that are specifically designed for UV printing. This means that the printer will be more reliable, efficient, and produce higher quality prints.

Many UV printers on the market are modified based on Epson printers, which were not originally designed for UV printing. This can lead to problems such as slow printing speed, reduced print quality, and decreased durability of the printer and unknow errors. Additionally, many of these modified printers use hacked AcroRip software, which can be unreliable and may cause issues with the printer’s performance.

With independent technology means that you will have a printer that is specifically designed for UV printing, with high-quality components and reliable software. While these printers may come at a higher price point than modified printers, they will likely save you money in the long run by producing higher quality prints and requiring less maintenance.

In summary, while modified UV printers may seem like a more affordable option, investing in a UV printer with independent technology can provide higher quality prints, greater reliability, and additional features that will ultimately benefit your business in the long run.

Our customers frequently express their challenges when sourcing UV flatbed printers from China. They find themselves overwhelmed by the multitude of options available, each varying in price. Vendors typically provide a few videos or pictures, but all the uv printers appear strikingly similar, making it extremely difficult to determine the most suitable choice. In the following section, we will delve into specific differentiating factors among UV printers available in the market.

RIP Software

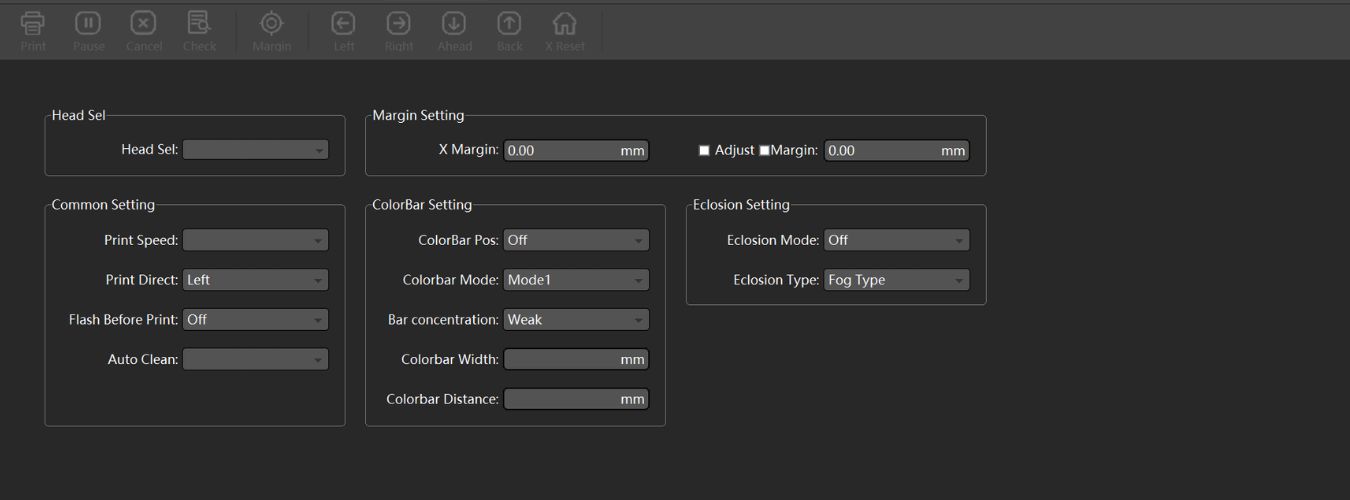

The RIP software, although often overlooked, plays a crucial role in managing printing tasks for flatbed UV printing machines. Graphics created in software like CorelDraw or Photoshop are edited and then uploaded to the RIP, which optimizes the design for maximum image quality during printing. Suntrix Rip software offers a range of specific features that set it apart, including various color curve options, a white spot layer, embossed layer settings, varnish and nozzle alignment, and eclosion settings. In comparison, most other RIP software options like Acrorip lack these comprehensive functionalities.

Printhead

There are two main types of printheads available: Epson and Ricoh. Ricoh heads are commonly found in large-size UV printing machine and are widely utilized in the industrial printing sector. On the other hand, Epson heads are predominantly used in smaller UV printers ranging from A3 to A1 models such as L1800, XP600, and I3200. However, determining the “best” printhead requires consideration of factors such as price, lifespan, and print speed.

The printhead is a vital component of UV printers and an important consumer spare part. Let’s compare three different printheads: I3200, L1800, and XP600.

The I3200 printhead offers fast printing speeds of 15 to 20 m2/h and has a lifespan of approximately 15 months. However, it comes with a high price tag of $700.

On the other hand, the L1800 printhead has a slower printing speed of 3 to 5 m2/h and a shorter lifespan of around 10 months. However, it is more affordable, priced at $120.

The XP600 printhead strikes a balance between performance and affordability. It offers a print speed of up to 10 to 12 m2/h and a lifespan of about 12 months. With a price of $250, it emerges as a well-rounded option.

Considering these factors, the Epson XP600 printhead stands out as a reliable and cost-effective choice in the realm of UV printer printheads. It offers a good balance between performance, longevity, and affordability, making it a popular choice among users.

Cooling system

One notable feature of UV flatbed printers is the inclusion of an LED lamp curing system that facilitates the drying of ink throughout the printing process. Typically, uv printers employ a cooling system to regulate the temperature of the lamp, and water cooling systems are commonly used in the market. However, We have introduced an upgraded cooling system that utilizes air/wind, simplifying the maintenance process. With this advancement, there is no need to monitor water levels or ensure timely water refills. Additionally, users no longer need to be concerned about the circulation of water when powering on the printer.

Auto Height Adjustment

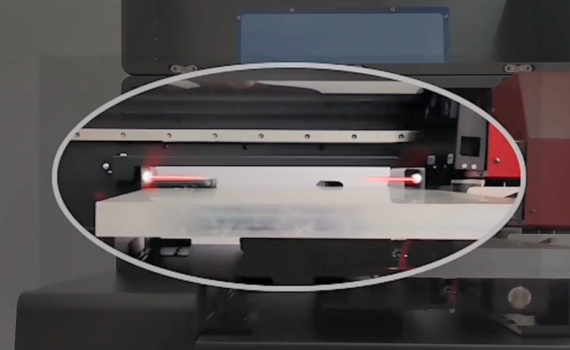

UV printers often incorporate automatic height adjustment as a necessary feature to achieve suitable print height and high printing quality. While other may require manual height adjustments, Suntrix stand out with their two infrared sensors positioned on the side of the tabletop. These sensors detect the movement of the substrate and automatically lower the print gap to the optimal height. Additionally, these sensors serve as a safety measure by stopping the table’s movement if it exceeds a specific distance, preventing any potential collisions between the product and the printhead. With Suntrix UV printers, users can enjoy the convenience of automatic height adjustment while ensuring precise printing and protecting the equipment from damage.

Ink System Device

Head clog issues can be minimized in digital inkjet UV printing machines through the use of specific devices. One essential device is the white ink stirring system. This system incorporates a built-in motor in the white ink tank that continuously stirs the ink, preventing precipitation and clogging.

Another effective solution is the printhead capping device. When the UV printer is idle, this device raises the printhead and provides a tight seal, maintaining moisture levels and preventing clogs.

Additionally, having ink-flushing functions in the RIP software can further reduce the likelihood of clogs. These functions enable automatic flushing of the printhead channels at regular intervals, ensuring the ink flows smoothly and preventing any blockages.

By implementing these measures, UV printers can significantly lower the occurrence of head clog problems. The white ink stirring system, printhead capping device, and ink flushing functions in the RIP software collectively contribute to maintaining optimal performance and reducing maintenance issues related to clogs.