Direct to Film Printing

DTF is printing the design onto a special film, which serves as an intermediary. The printed film is then transferred onto fabric using a heat press. This process is more efficient and cost-effective than traditional silk screen printing, as it eliminates the need for a film or frame.

DTF printing can print larger size of fabric compared to DTG Printer, especially when it comes to printing on a wider range of fabrics. While DTG printing is mainly suited for cotton blends, DTF printing can be used on diverse materials such as vinyl, polyester, nylon, and sports fabrics. Furthermore, DTF printing utilizing a film roller facilitates continuous printing of a larger surface area of the film design, which makes it particularly well-suited for high-volume production.

In general, DTF printing is an excellent option for expanding your printing business and catering to a diverse range of textile material printing needs.

With width 30cm and affordable price A3 dtf printer, dtf kit like powder machine and roller will be needed.

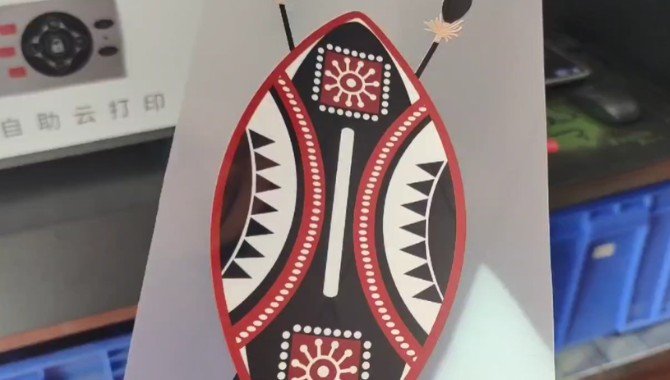

DTF Printing Product

DTF Printing Features

DTF printer is enable to print on not only on cotton, but all fabrics like polyester, nylon, canvas, jeans, hoodies etc.

DTF ink is a type of textile ink that, once fixed by melting powder and transferred onto fabric using heat, becomes exceptionally durable and long-lasting.

Fast-speed printing with 6 meters film per hour. Transfer the design on clothes with heat press for 20 seconds.

DTF ink consumption is more cost-effective than textile ink. Compared with screen printer and it does not require frame or film.

See The Video How It Works

If you are considering starting a DTF printing business for fabric items like garments and hats, you will need several key components, including a printer, a film transport system, and a powder machine.

The process of how a DTF printer works is as follows: first, select an edited design and output it through PrintExp software. The design is then printed onto a long run of PET film using a film roller. The film transport system synchronizes its movement with the printhead to ensure that the design is accurately aligned and positioned during the printing process.

After printing the design onto the PET film, the next step is to cut it out and place it onto the fabric. Heat press machines are available for purchase at Homedepot. Each design requires approximately 20 seconds of heat pressing to allow the ink to dry and for the film to be removed. At this point, the entire printing process is complete.

Powder Machine

Powder shaking machine is a device that is used to distribute powder evenly and efficiently after the film has been printed. This unique powder adhesive coating is what gives DTF prints their signature soft touch. The ink’s durability will be greatly enhanced by applying melt powder and subjecting it to a heat press.

High Qualiy

Like traditional digital printer with CMYK colors works by combining four colors. One notable difference is that it doesn’t involve direct printing onto the garment; instead, the ink is transferred onto a powder layer, resulting in brighter colors, particularly when printing on dark materials.

DTF OR DTG

If you are new to the field and trying to decide which technology to choose between DTF and DTG, there are a few factors to consider. Firstly, it’s important to understand the differences between the two technologies and what their strengths and weaknesses are.

DTF is a new printing technology that uses a specialized printer to transfer designs onto a transparent film, which is then transferred onto the garment using a heat press. DTF offers better high-quality prints with vibrant colors and is suitable for a wide range of fabrics, DTG is used for cotton printing.

If you work with a range of textile products that include materials beyond just cotton, the DTF printer is an ideal choice. The DTF printing process utilizes a melt powder layer that enhances the vibrancy of colors on fabric, resulting in brighter and more vivid prints. However, it is important to note that the color layer produced by DTF printing is thicker than that of DTG printing, which can affect air permeability. Furthermore, while the DTF printing process offers superior color vibrancy, the DTG printing process is generally considered simpler and easier to use.

DTF Printing Applications

Printing on the front of a t-shirt is relatively simple, but printing on the sleeves or a thick hoodie sweatshirt can be more challenging. In such cases, DTF printing is a better option because it allows you to heat press on any hard-to-reach areas of the garment.

Baseball caps are a popular item to print on, but traditional DTG printers have difficulty properly fixing the design onto the curved surface of the cap. Fortunately, DTF printers have made it possible to directly print designs onto hats with irregular shapes.

For printing long flags, the size can be too large to fit on DTG printers, especially if the banner material is not cotton. DTF printing can be a better option which without any material limitations and without size constraints.