A3 UV DTF Printer

Commercial A3 ST1900 UV DTF printer

- Width 11.8 inch

- Dual XP600 printhead with CMYKWW+VVVVVV

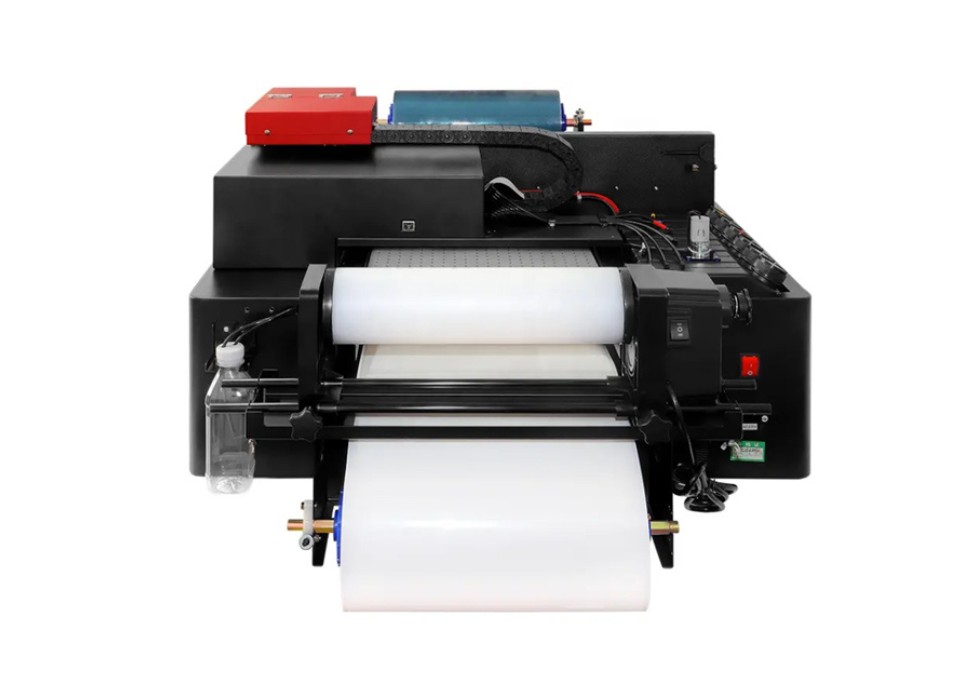

- With roller kit

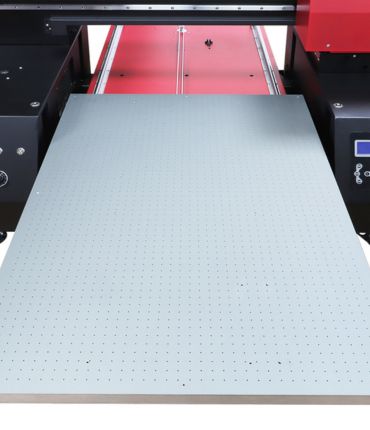

- With vacuum table

Why Do We Need UV DTF Transfers

If you are a UV printer user, you may encounter difficulties when attempting to print on uneven products such as mugs, bottles, and other round objects. UV printers are typically designed for flat substrates, limiting their applicability. However, UV DTF (Direct to Film) printers offer greater flexibility compared to conventional UV printers. These printers utilize PET transfer film, which can adhere to various substrates without any limitations. This means that you can apply the film onto almost anything, enabling you to print on a diverse range of objects, including uneven and rounded surfaces.

Main Specifications

| Print Size | 11.8 inch width |

| Print Depth | 100 meters roller |

| Printhead | pcs XP600 |

| Ink Colors | CMYKWW+VVVV |

| Ink System | White ink stirring system |

| Voltage | 110~220V , All plug standards |

| Dimensions | 43.7 x 30.3 x 18.1 inch |

| Resolution | 2880 dpi |

| Software | Windows PrintExp Photoshop |

| Warranty | 1 years |

How does UV DTF printer work?

Essentially, the UV DTF printer follows the same printing process as a regular UV printer, with the main difference being the inclusion of a PET film as an intermediary medium. UV printers come equipped with a DTF kit specifically designed for feeding films.

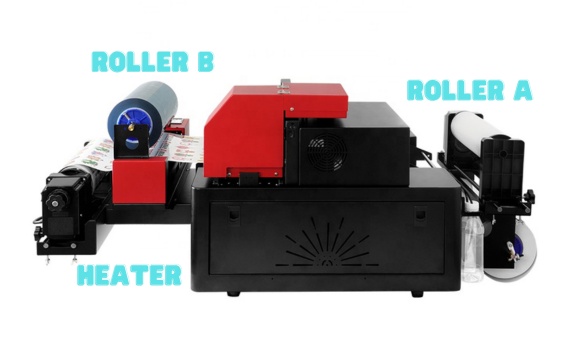

The UV printer features a film roller at the back, allowing for the feeding of A film onto the table, which is then connected to another roller at the front. Simultaneously, there is a B film roller positioned on top of the front roller, which adheres the B film onto the A film after printing is completed. A heat device located under the B roller is used to laminate and heat the A and B films. This entire process is automated and coordinated with the movement of the table.

The final step is removing the A film and applying it to the desired products. The design can be seen on the underside of the B film, and peeling off the B film leaves a clean design.

What are the Advantages of UV DTF?

- Can print any type of materials

- Keep same durable UV inks

- PET film sticker can keep months for coming order

- Max printing solution to 2880 DPI

- High-quality CMYK full colors

- Competitive price to start printing business

- One-on-one customer services and setup videos

- Easy operateions, no heat, no film lamination

What are the differences of A3 ST1900 UV DTF Printer